To learn more about iVT, please read through this presentation first given at Aachen in October 2017

iVT Overview

Unfortunately this content does not scale well onto mobile devices. Rather than give you a bed experience, you can download a pdf of the presentation slides using the button. Thanks.

Download pdf

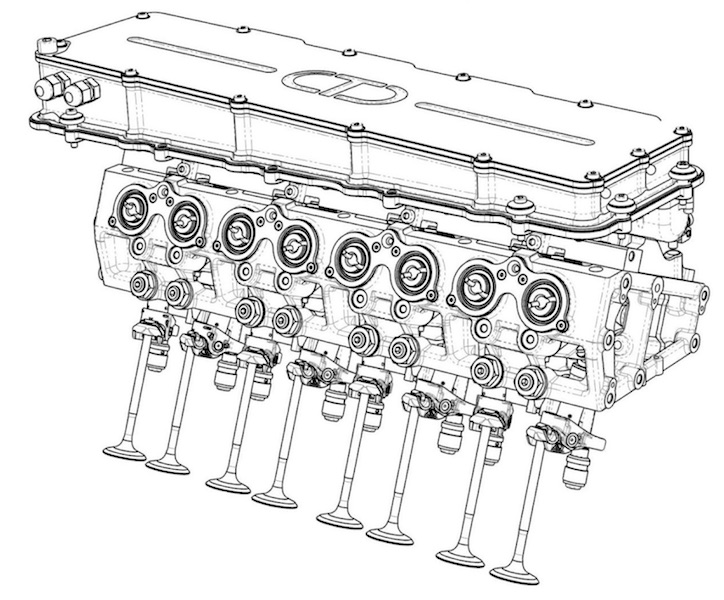

What is iVT

- iVT is a full authority, purely electro-mechanical, variable valve actuation system for piston engines

- Unprecedented level of control – valve by valve

- Full, fast feedback control throughout the event

- Can be used on both inlet and exhaust valves, double events possible – an HCCI enabler?

- Digital control of gas exchange, the last controllable combustion variable

Intelligent Valve Technology

- Uses an individual, electrically actuated desmodromic mechanism per valve or valve pair

- No mechanical drive from the crankshaft

- No conventional valve (or “helper”) spring

- Compliance to allow for seating loads, expansion etc. is built in to the drop link

- Operates on 12 or 48 volts

Operating Modes

- Full lift = full rotor rotation

- Part lift = part rotation + return

- Rotor velocity never constant

- Rotor “parks” between most events

- Every event is independent of both its predecessor and its successor

What does iVT Offer?

- Complete, infinitely variable, phase control

- Complete, infinitely variable, period control

- Complete, infinitely variable, lift control

- Event shape control – and not just MOP shift

- All virtually independent of each other

- Multiple event, no event

iVT Installation

- Actuator axis perpendicular to crankshaft

- Electronic control unit compliantly mounted over or alongside the mechanicals

- Packages within normal N-S and E-W layouts with conventional bonnet clearances

Electro-mechanical Layout

- Mechanically, the linkage contains nothing unfamiliar or of unusual precision

- Each actuator is an 8-pole, permanent magnet machine

- The stator is segmented and shared between actuators, maximising torque capacity and efficiency

- Asymmetry further improves performance/unit package volume and weight

Control

- Master controller requests the required valve event

- Each actuator is under independent position control

- Local actuator controller determines the target rotor trajectory for minimal energy consumption

- The target trajectory is dynamically adjusted, compensating for transient engine behaviour during each valve event

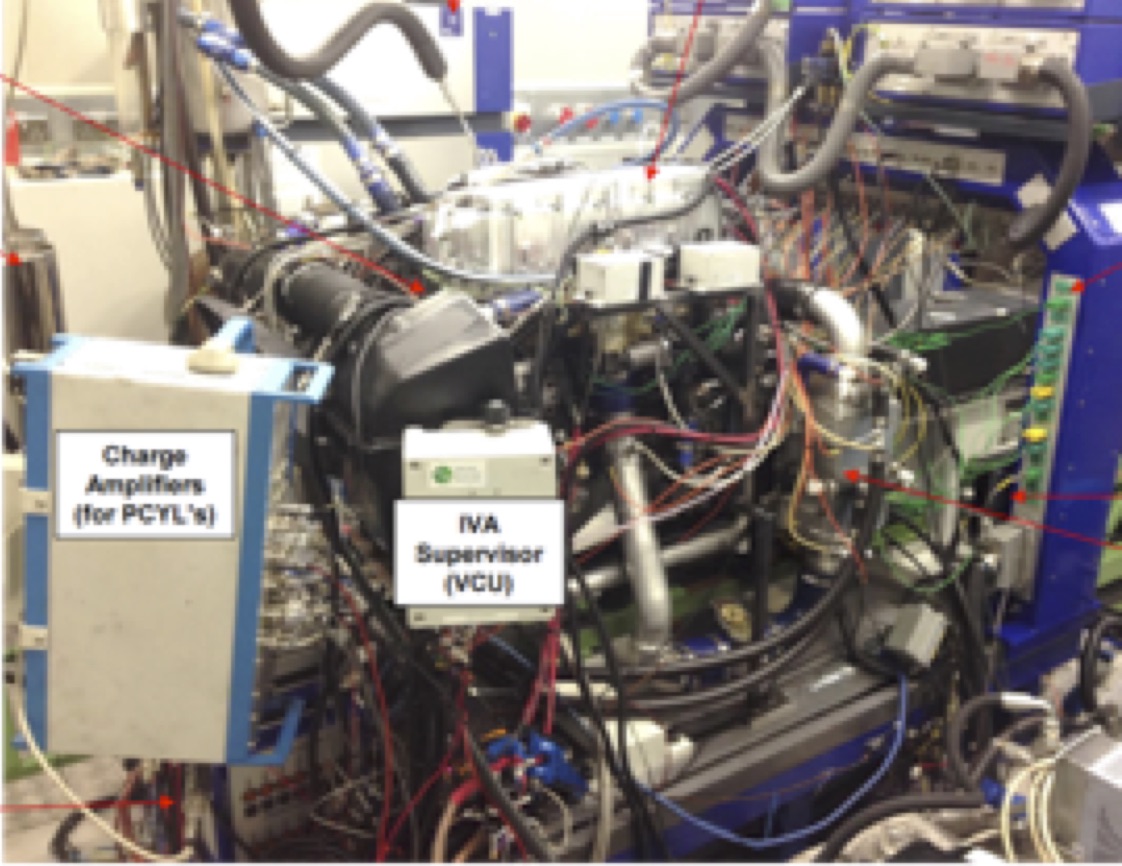

Testing

- Testing has been conducted both on test rigs and on the dynamometer

- The first iVT modules have been designed for the inlet valves of a Jaguar Land Rover Ingenium engine

- Max valve lift reduced to 7.8mm

- 1D analysis suggested similar performance- timing/period compensating for reduced lift

- The dynamometer results confirmed the predicted performance

- Eliminates piston interference

Dynamometer Testing

- 10 “minimap” steady state points defined

- Large DoE experiment completed (Inlet only)

- CO2 improvements up to 7.5% recorded

- Optimised events established

- The VVT capability required is greater than any other available system

- Even greater iVT dynamic capability is now in development and will provide further benefit

Results Analysis

- CO2 results achieved with iVT power sourced from the alternator – opportunity for smart charging?

- The CO2 benefits come from 3 sources:

Pumping loss reduction

Heat release rate and knock sensitivity increase

Parasitic loss reduction

Event Consistency

- Valve position was measured on the fired engine for 300 consecutive events

- An example of the control achieved is shown

- Measurements of event quality have been established in order to ensure that other development improvements, e.g. power consumption, can be measured against a common standard

Optimised events

- Throttle wide open in all cases, including idle

- Single valve mode often best

- Both EIVC and LIVC capability needed for different conditions

- Late MOP useful for some events

- Only steady state and the simplest iVT strategies have been explored so far – there is much more to come

Other Aspects of Note

- VERY low mechanical noise

- Transient valve response: 0-100% in one cycle

- Significant detonation sensitivity improvement

- Cranking torque reductions of ~30% through reduced pumping loss have been demonstrated

- There are hybridisation synergies yet to be explored but deletion of the timing drive is an obvious benefit

- Demo car available now

- Single cylinder R&D programme support possible

Cost and Affordability

- On-costs have been estimated as a joint effort – a Tier 1, Jaguar Land Rover and Camcon

- The CO2 benefit, even on the basis of today’s steady state results alone “pays for” the system

- There is much more to come in terms of CO2 benefits

Next Steps

- The next generation iVT prototypes are being procured now.

- The new actuators will be smaller, lighter, cheaper, >40% lower electrical power demand

- Improved dynamic performance will mean further improved CO2 results

- Exhaust actuators and 16V engine testing included in the next stage of the programme

- And then: diesel, including heavy duty

Like to know more?

Please give us your contact details and we will be in touch