You can download a pdf of our single cylinder brochure by clicking the button below

Download brochure pdfIf you would like to get a quote for an iVT single cylinder system, we will need certain information from you. You can fill out this online form including your contact information, and we will contact you to discuss your needs further

Request a quoteIntelligent Valve Technology (iVT) from Camcon Auto brings real-time digital control to the gas exchange process in combustion engines. Dramatically reducing emissions and improving drivability, iVT is designed for manufacture and affordability.

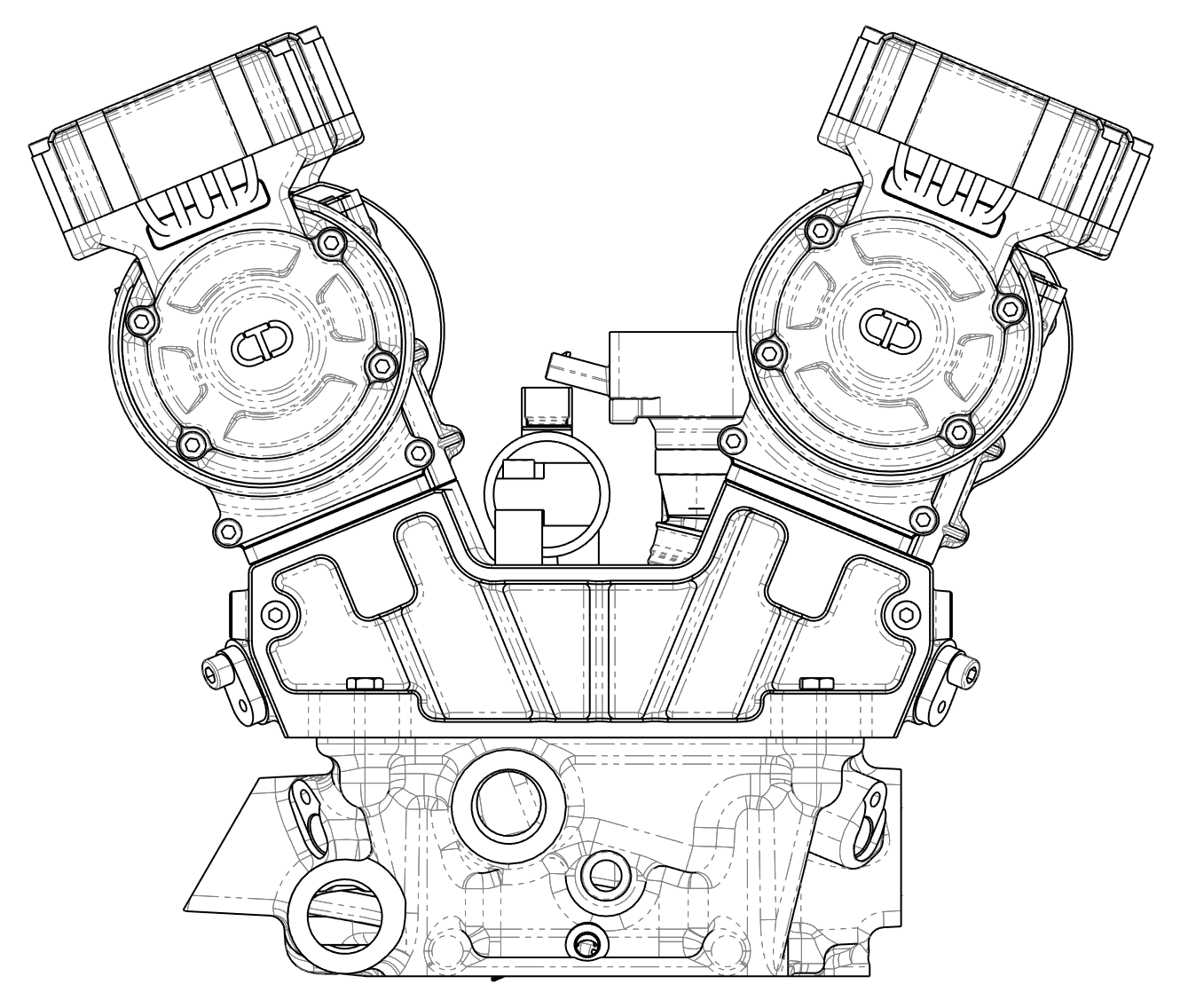

Camcon Auto makes and sells iVT systems compatible with all gasoline single cylinder combustion development engines, enabling on-the-fly cam changes, innovative combustion strategies - significantly reducing development cycle time and cost.

A bespoke adapter plate is designed to provide the mechanical interface between the Client’s single cylinder engine and the SCI mechanism.

Our SCI Systems use 4 independent iVT actuators (one per valve). Each iVT rotary actuator is under full-time, fast feedback control permitting the generation of any valve timing, period or lift required at the touch of a button. Both conventional and unconventional event profiles can be achieved. The conventional camshafts are completely eliminated and valve position can be monitored throughout the event using a specialised sensor.

A single cylinder engine using this equipment can either reduce the time taken to gather a set of combustion data covering a given set of valve event options by orders of magnitude or permit hugely more complete data sets to be gathered in the same development time. In practice, much larger data sets will be gathered, allowing much more detailed response surfaces to be determined in a fraction of the time a conventional SCE programme would take.

The system is compact, quiet and, apart from the actuators fitted to the cylinder head assembly, and a dedicated absolute crank position sensor requires only a power supply in the cell plus a laptop with a custom interface to control the system. The entire system including valve position instrumentation and power supply can be provided ready to interface with your data acquisition equipment.

Additionally, IVA permits “Event Shaping” – the maximum opening point can be skewed within the event, the event feature a dwell period at full lift, other, more elaborate shapes are also possible. Multiple events within one engine cycle can be achieved – allowing extra exhaust events for HCCI or CAI combustion studies for instance, or running in 2-stroke mode (or 6 stroke or 8 or 12).

(c) Camcon Auto Ltd 2015-2018

Camcon Auto Ltd. Registered in England and Wales No: 07033987

VAT No:GB 974860964